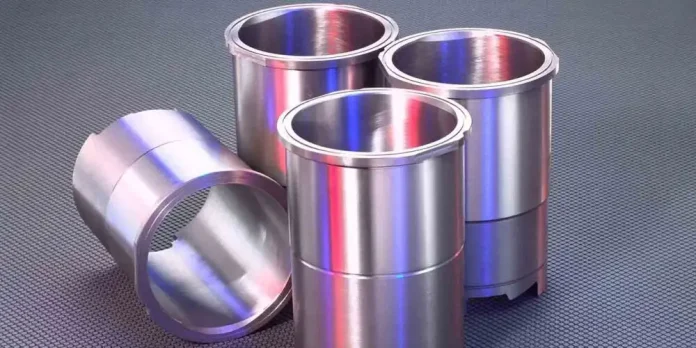

In today’s rapidly evolving industrial landscape, engine components remain central to transportation, agriculture, construction, and energy sectors. Among these, custom cylinder sleeves play a unique role. They extend engine life, enable refurbishments, and provide performance tuning for machines that must operate in challenging conditions.

While advanced economies often replace entire engines, emerging markets frequently prioritize repair, rebuild, and customization. This difference creates both opportunity and risk for businesses considering investments in custom sleeve manufacturing and distribution.

Growing Demand for Cylinder Sleeves

Emerging markets such as India, Brazil, Nigeria, and parts of Southeast Asia rely heavily on diesel trucks, agricultural machinery, and stationary power units. Many of these engines operate under harsh conditions, including poor road quality, inconsistent fuel quality, and heavy-duty cycles. Replacement engines are expensive and often imported, but a properly designed cylinder sleeve can restore an engine’s function at a fraction of the cost.

Custom cylinder sleeves add value where “off-the-shelf” solutions do not fit older or nonstandard engines. With fleets running beyond their intended lifespan, demand for tailored sleeves is rising. Suppliers that can respond quickly with precise dimensions, metallurgical quality, and reliable delivery gain an edge in these markets.

Business Potential

Repair-Centered Economies

In many emerging regions, maintenance culture emphasizes “fix rather than replace.” A workshop capable of installing a custom sleeve can extend the working life of tractors, buses, or generators by years. This creates a consistent revenue stream for local distributors and offers manufacturers long-term business relationships rather than one-off sales.

Aftermarket Growth

The aftermarket for custom mechanical parts is expanding. Vehicle ownership is increasing, but supply chains for genuine OEM parts remain constrained. Independent service centers rely on adaptable suppliers to meet customer needs. Custom sleeves fit well into this trend, allowing smaller players to compete in servicing engines from multiple brands.

Manufacturing Partnerships

Emerging markets provide fertile ground for partnerships with local machine shops and foundries. For instance, integrating a hot forging service alongside sleeve production can enhance capacity for other components such as pistons, connecting rods, or flanges. Such bundling helps suppliers diversify income streams while anchoring themselves in the region’s industrial ecosystem.

Technology Transfer and Training

Companies that invest in training local technicians to measure, fit, and test sleeves can secure loyalty. Technical support—often overlooked—can become a differentiator. Emerging-market customers value not just the part, but the know-how to use it properly.

Risks and Challenges

Quality and Counterfeiting

The biggest risk in emerging markets is inconsistent quality. Low-cost producers may cut corners on metallurgy, leading to premature wear or failure. Counterfeit parts also dilute trust. To mitigate this, businesses must enforce traceability, certifications, and robust testing.

Supply Chain Volatility

Global steel prices fluctuate significantly, and shipping delays are common. Emerging economies often face port congestion, customs complexity, and logistical bottlenecks. Firms that localize production or maintain buffer stocks stand a better chance of meeting customer expectations.

Regulatory Uncertainty

Custom sleeves may fall into gray areas of local regulation. Some countries demand emissions compliance even after a rebuild, while others lack clear rules. Suppliers must balance meeting international standards with adapting to local enforcement realities.

Payment and Financing Risks

Credit systems in emerging markets are often less reliable. Workshops may demand extended payment terms, increasing financial exposure for suppliers. Building trust requires flexible financing strategies, sometimes in partnership with banks or microfinance institutions.

Strategic Approaches

To succeed, companies must treat emerging markets as long-term plays, not opportunistic ventures. Recommended strategies include:

- Localized Inventory: Establish regional warehouses to shorten lead times.

- Partnerships with Distributors: Collaborate with trusted local suppliers who understand cultural and market nuances.

- Tiered Product Offerings: Provide both budget-friendly sleeves and premium, long-life options.

- Digital Engagement: Use online platforms to showcase technical specs, provide installation tutorials, and build brand awareness.

A phased approach—starting with pilot distribution in one market, then expanding—reduces exposure while proving demand.

Outlook

As industrialization and motorization accelerate, the need for cost-effective repair solutions will continue to grow. Custom cylinder sleeves embody a balance of engineering precision and affordability, making them particularly relevant in economies where engines are expected to run for decades.

The opportunity is clear: businesses that align quality with affordability, and back it with local engagement, can capture enduring value. Yet the risks—quality lapses, counterfeit products, and financing challenges—demand careful management. Companies willing to invest in resilience, partnerships, and trust will find that emerging markets are not just places to sell parts, but platforms to build lasting industrial presence.